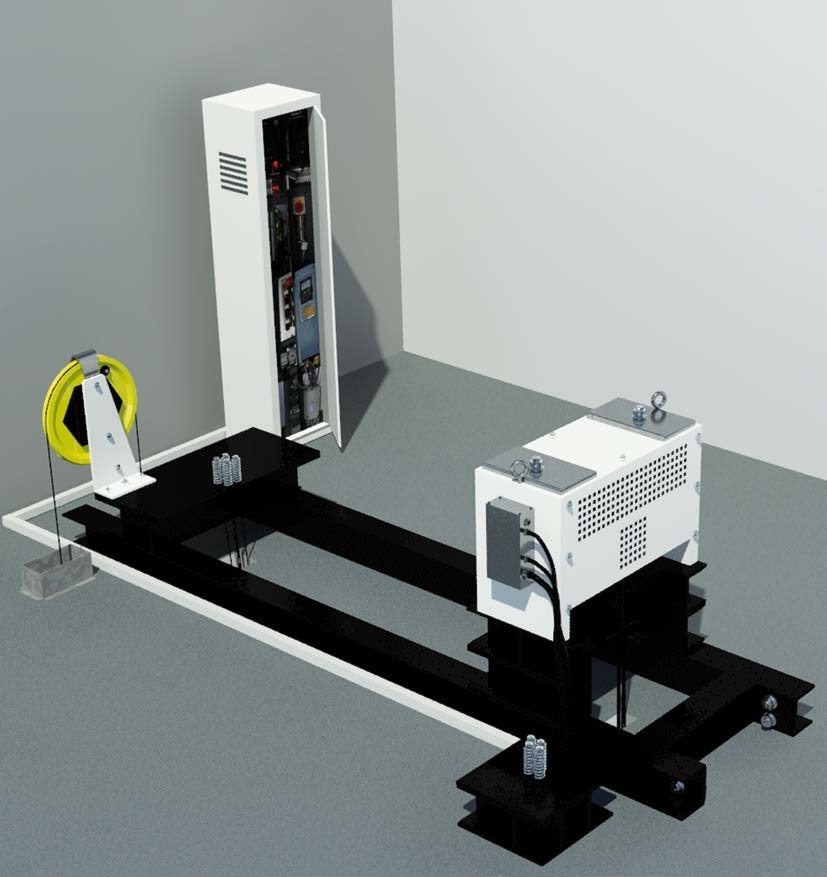

MACHINE ROOM SYSTEM

- gearless synchronous traction machine - lift machine is located in the machine room above the shaft - high energetic efficiency 50% saving compared to geared machines, and as much as 70% saving compared to hydraulic machine - ecological operation, drive system without using oil - frequency regulation, inrush currents reduction

COUNTERWEIGHT

- a special type of counterweight - thin plate (thin model), width 70 mm up to 110 mm, standardized for counterweights with the carrying capacity between 250 kg and 1,000 kg.

LANDING DOOR AND CABIN DOOR

- automatic doors of all sizes controlled by frequency regulation - optional various types of special surface finish designed by the TDS - EKOCLOSE – the new generation automatic door - optional synchronous door control motor, as much as 50% saving compared to conventional door - RENO - the new renovation door series 4-panel, door horizontal clearance of 700 mm. Suitable for shaft width of 1,200 mm and more - frameless door

CABIN FRAME

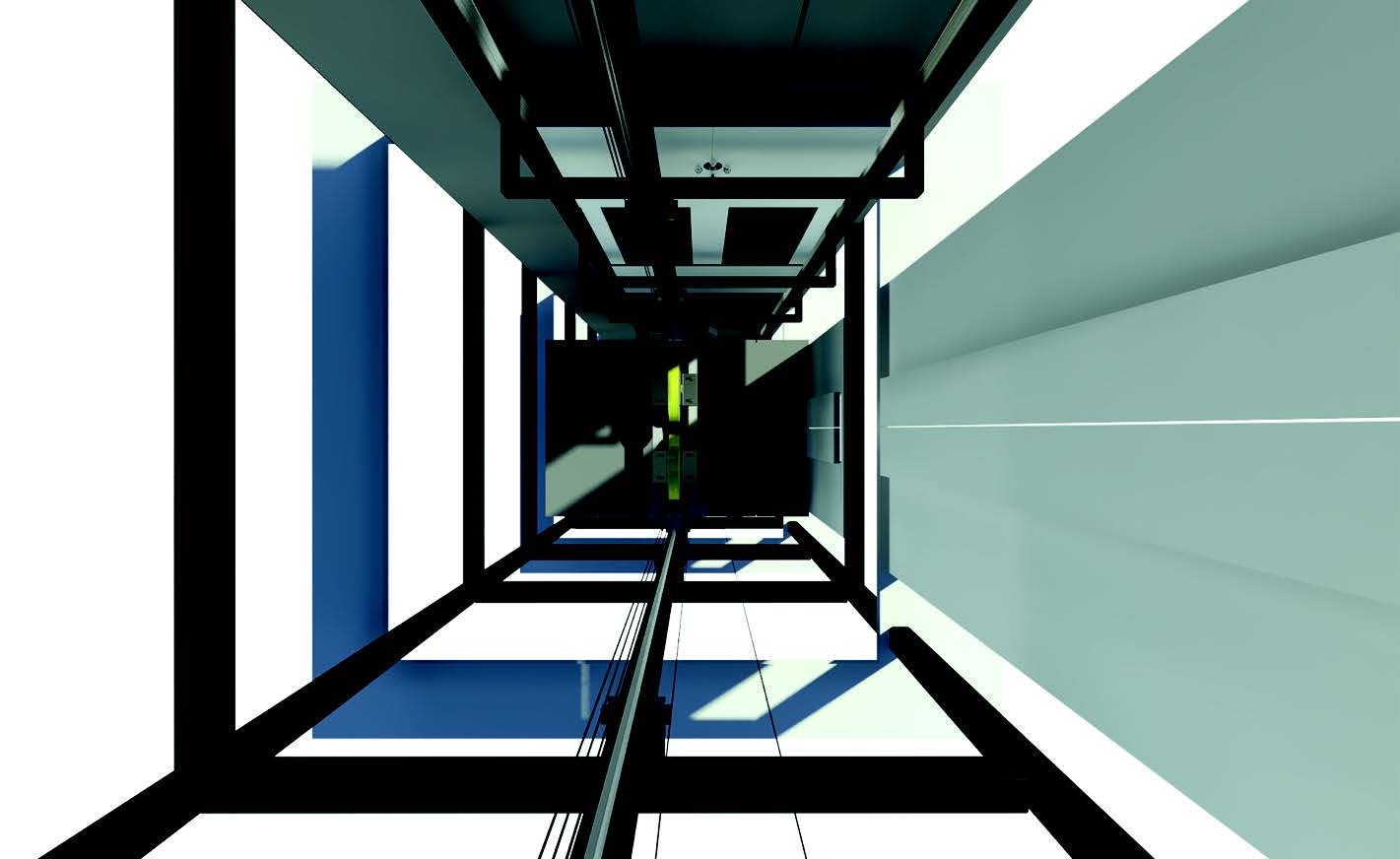

- cabin frames for hydraulic lifts and traction lifts with roping (1:1, 2:1, 4:1) |

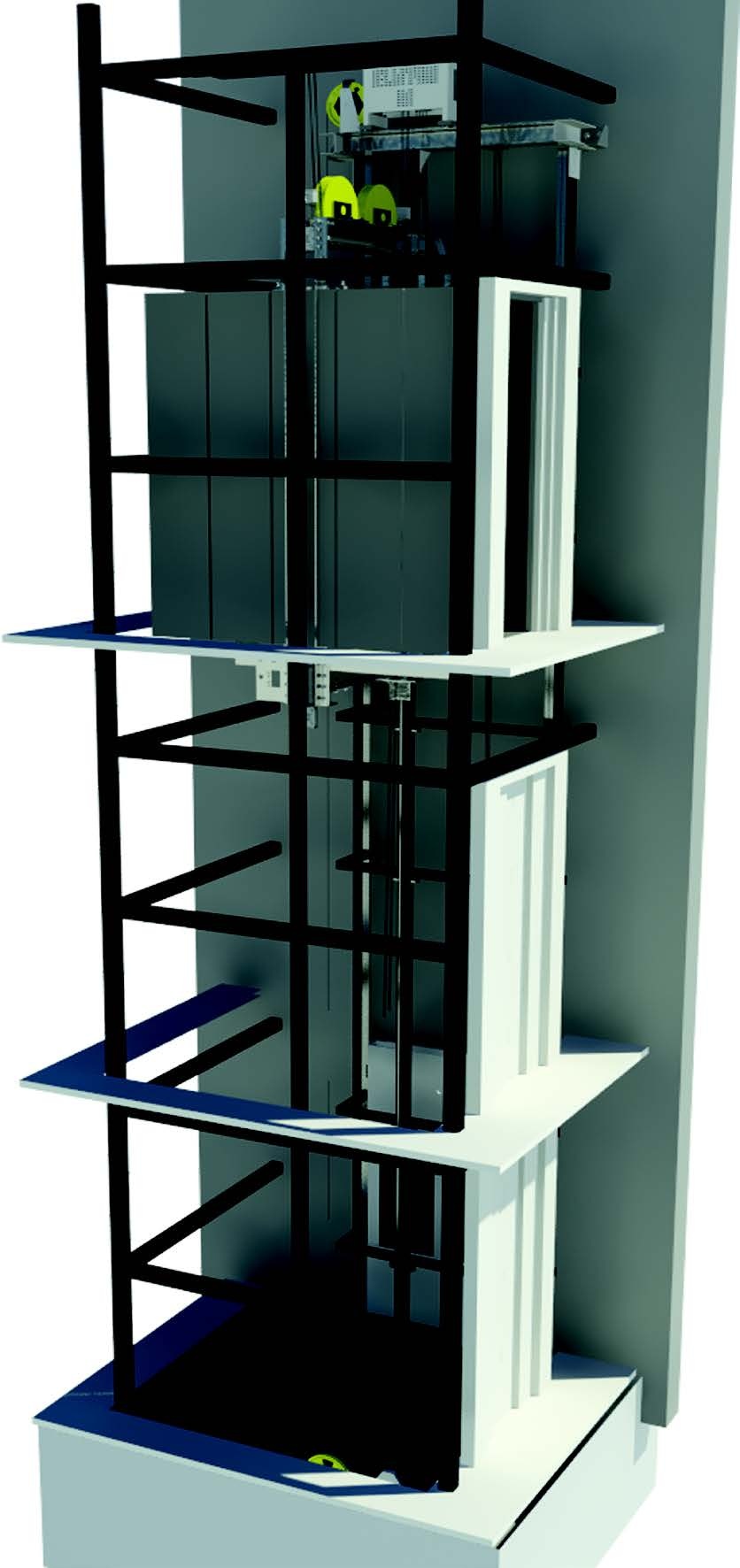

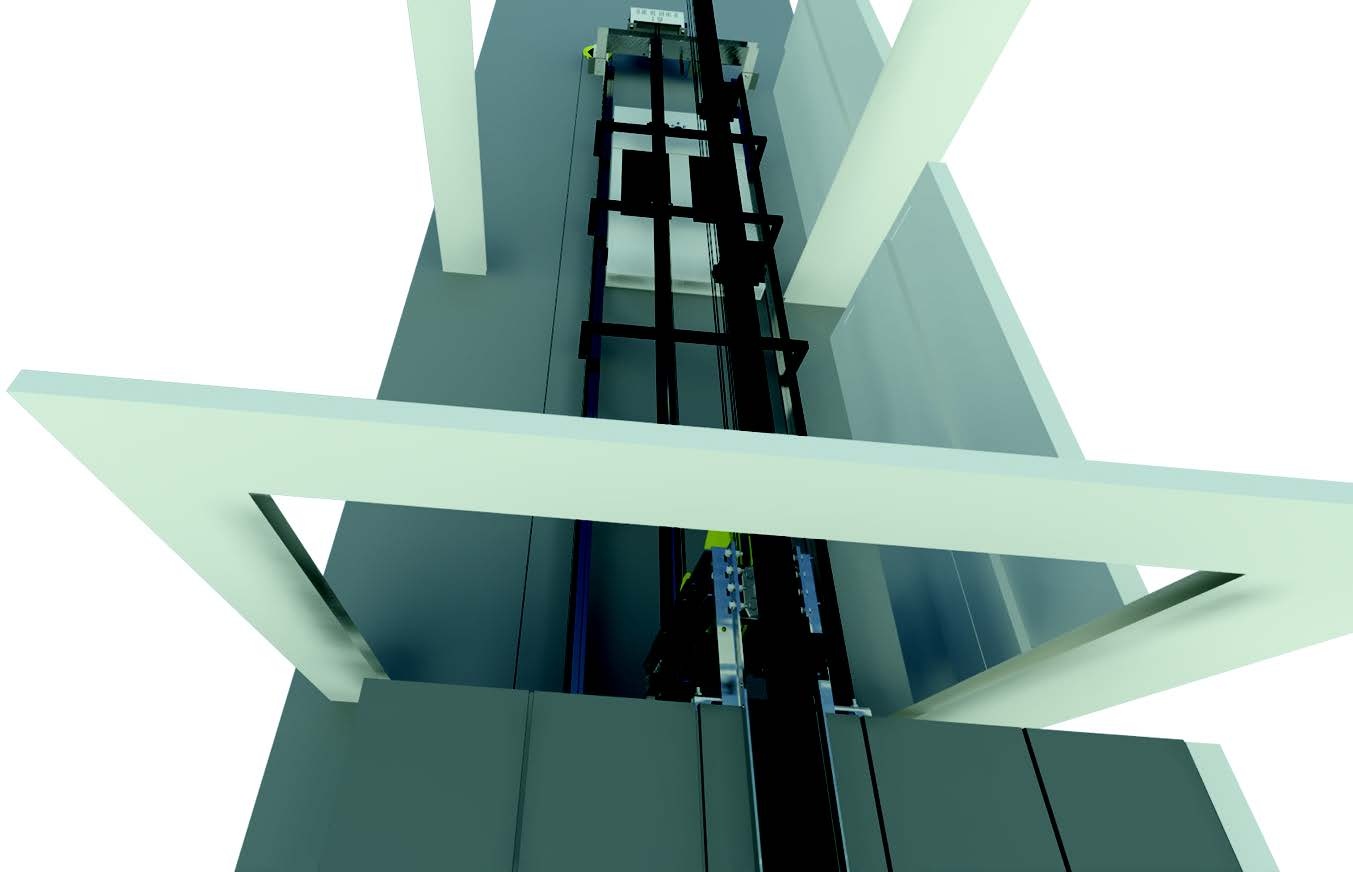

Shaft with a machine room lift

|

LIFT CONTROL

- the most modern microprocessor control system of ACT and ACH series - compatible control for all types of systems - remote monitoring via ETH ERNET, INTRANET, INTERNET is the standard for all systems. - interconnected with the ElevArt security information system.

CABIN OPERATION PANELS AND LANDING OPERATION PANELS

- renovation series of landing operation panels and cabin cooperation panels mounted on the surface - the newest set of landing and cabin glass touch operation panels

CABIN

- cabin in versions cs, cls, gls - ps - LED lights with as much as 80% saving - anti slip PVC flooring - optional use of air purifier with ozone sterilization (abasys). - installation of the Elevart security information system. - full-area light barrier - tensometric weighing in the cabin |

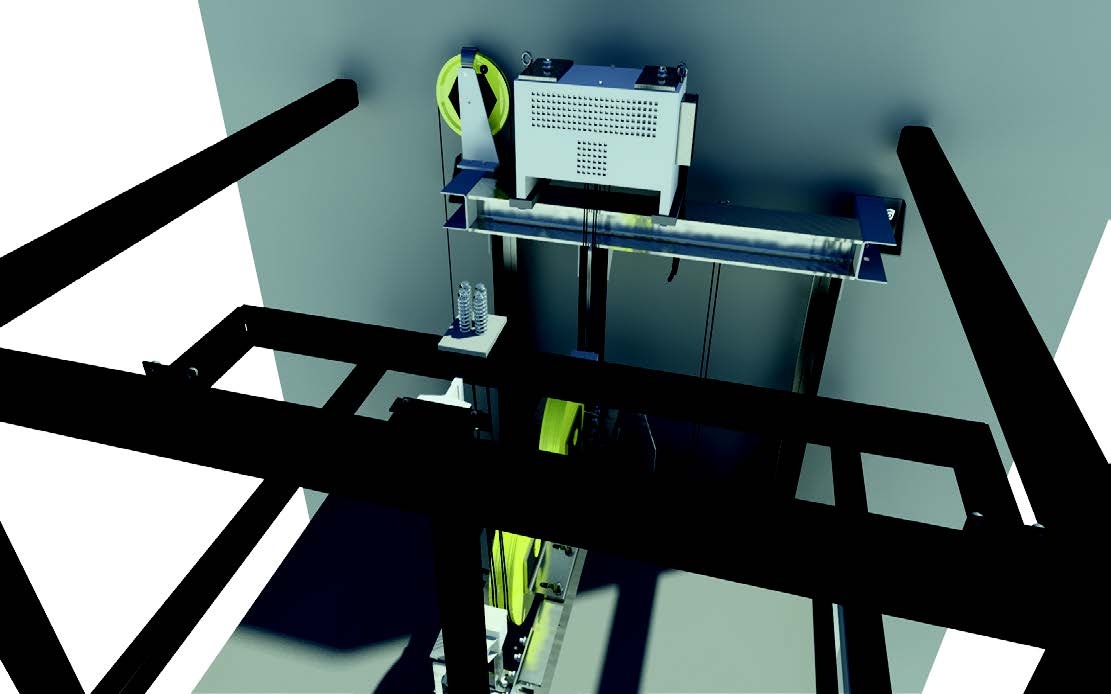

MACHINE ROOM-LESS SYSTEM

Lift machine located in the top section of the shaft or in the pit. Gearless synchronous traction machine. High energetic efficiency - 50% saving compared to a geared machine and as much as 70% saving with a hydraulic machine. Ecological operation - drive system without using oil. Frequency regulation – inrush currents reduction.